Food and Beverage

Stainless pressure vessels used in a food manufacturing facility.

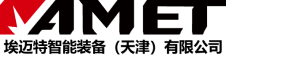

AMET produced elevating seam welding system used for stainless steel pressure vessel manufacturing.

Manipulator system and positioner with specialized tooling for manufacturing large food grade storage tanks.

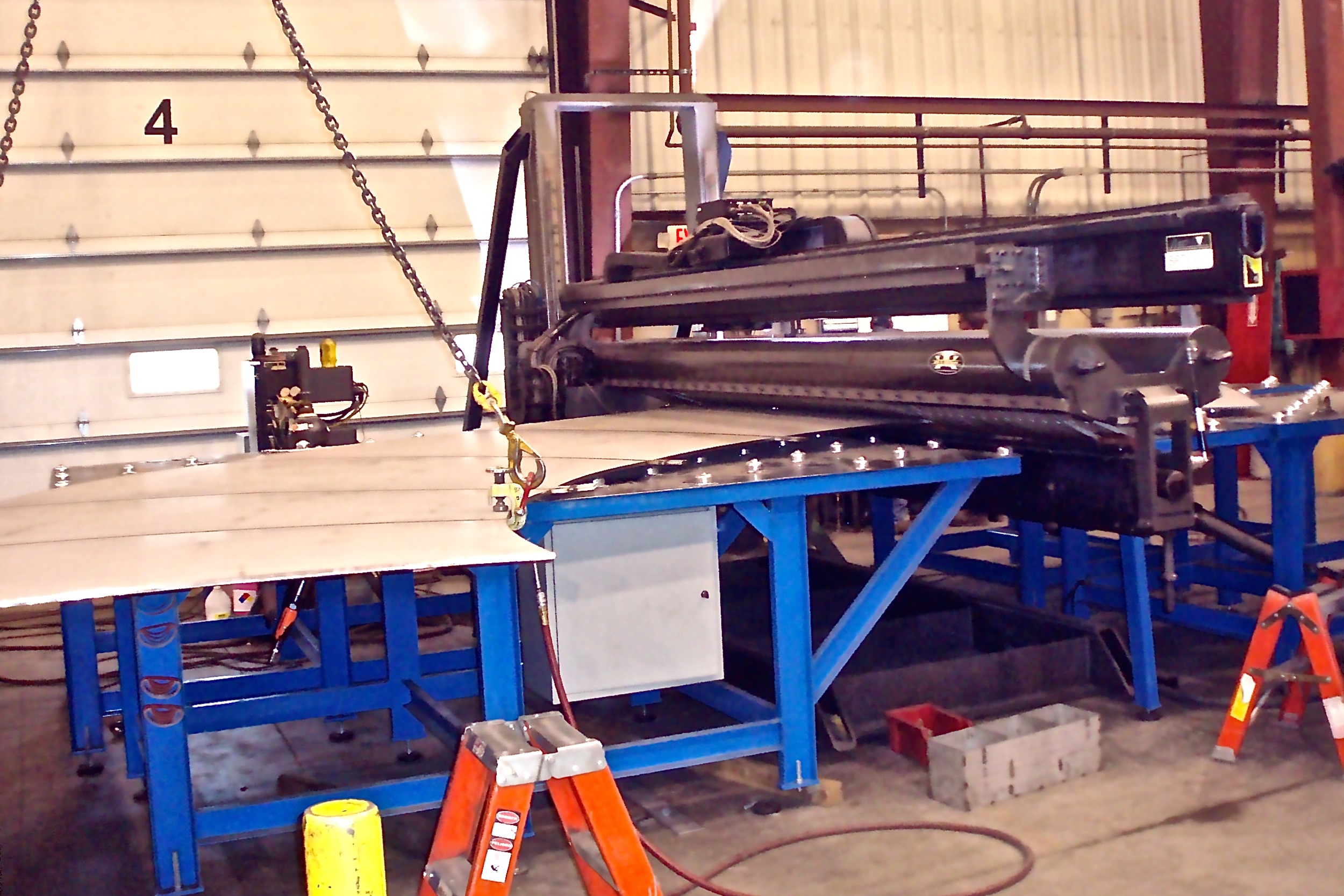

AMET seam welder with part loading rollers at customer facility producing stainless steel containers.

General

AMET provides systems to the food and beverage industry for making stainless steel vessels and containers. We build GTAW, PAW and “Dual Arc” systems to our customer base. The XM is ideally suited for controlling one or multiple power sources for Dual Arc welding (Plasma + TIG) and precise velocity and positioning control of the motion axes.

Precision is key for food-grade stainless steel applications. Filters, storage vessels, cooking vessels and other items used in the food industry require high quality welds. We provide complete turnkey systems equipped with our precision controls. We have also retrofit several of our customer’s existing systems with AMET controls to increase precision and consistency.

Whether you need a system for performing circumferential, longitudinal, or both welds, we have the solution to meet your requirements.

Related Products

Case Studies

The Need

High quality longitudinal and circumferential welding of stainless steel food-grade components requires purging/backing gas to eliminate oxidation. Integrity and consistent performance are also essential when welding filters, storage vessels, cooking vessels and other items used in the food industry. Full penetration welds are critical for maintaining joint integrity.

Precision motion for welding operations are essential to ensure consistent and reliable operation. Non-precision motion can cause inconsistent welds, which may lead to premature component failure, resulting in facility damages, expensive component replacement / rework, and losses in productivity.

Solution

AMET offers a full line of linear seam welders, welding lathes, and column and boom manipulator systems for small and large applications. These fixtures, when coupled with AMET’s XM Controller, offer precise controls and backing gas capabilities. The XM offers the ability for gas on/off control with manual flow meters and an optional upgrade of gas on/off control with programmable flow rates for TIG and Plasma welding.

The seam welders feature servo motors with encoder feedback driven travel carriages for positioning and velocity control. Our seam welders are available with optional backing gas inserts along the length of the joint to ensure proper gas coverage on both sides of the part.

Weld lathes are equipped with encoder-based servo motor driven rotation of the headstock and include thru holes for backing or purging gas.

Manipulator systems can be fitted with precision boom motion, welding axis quality motion of the travel cart for large longitudinal welds, and rotary control of turning rolls for circumferential welds. We can implement backing or purging gas capabilities into these systems as well.

Result

With AMET’s precision controls over motion and the integration of the welding power supply settings on the XM, the necessary system controls are available in a central location. Our systems also include gas and water flow sensors to ensure the presence of gas flow to the shield and trailing/backing gas fixtures, and water flow to the water-cooled components of the system such as the weld torch or water-cooled mandrel. This helps prevent oxidation due to lack of gas and also helps prevent damage or warping due to overheating, resulting in a higher quality product.

Our advanced control systems, extensive experience in the automated welding industry, excellent customer service staff, and wide array of welding fixtures purpose-built for stainless steel welding, ensure that we will be able to provide a system to meet your needs. Our complete systems will help you increase productivity, weld consistency, and overall weld quality.